Overview

As part of the Operation Warp Speed initiative for freezing and storing the COVID-19 vaccine, Southland provided design-build services to deliver a 1,100-pallet pharmaceutical cold storage system for a confidential client's existing warehouse. The project scope included a -40° blast freezer and a -20° storage freezer.

Our Approach

To deliver the new system for this turnkey project, Southland provided evaluation and design services and utility relocation, installing the equipment, and managing all associated trades and infrastructure modifications.

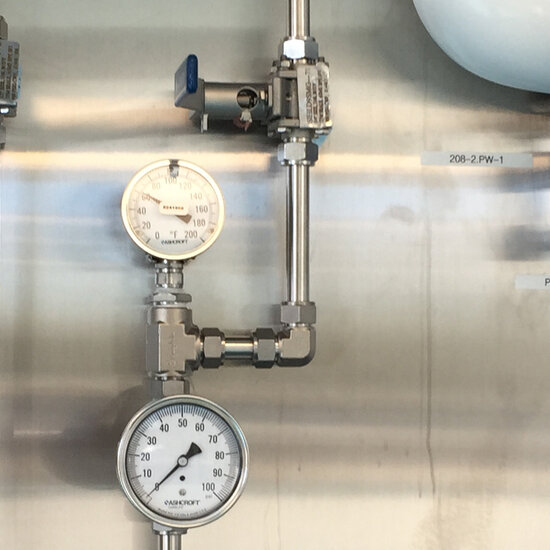

To accommodate the box height, the compressed air system, piping for water and natural gas, and other utilities were permanently relocated. The system was designed with 100% redundancy with the emergency generator, fire protection, lights, and temperature controls tied into the Building Management System (BMS).

Additionally, Southland administered three-stage validation support for the quality control group and reviewed and advised on the URS.

Result

Through the sole-source, design-build relationship with the client, Southland enabled swift mobilization and fast-track delivery, completing the project in just six months. All work was performed following the client's COVID-19 protocols and the project was designed with future versatility in mind to adapt to necessary changes. At the same site, Southland also designed and installed a -20° freezer, continually providing monthly maintenance on the equipment.

Overall, Southland successfully supported this confidential client during the height of the COVID-19 pandemic and initial vaccine response.

Successful Partnerships

Owner: Confidential

Architect: JacobsWyper