In today's world, energy efficiency projects should be thought of as more than a component upgrade, but rather as a strategic enabler of long-term resilience and operational value. As energy demands rise, infrastructure ages, and sustainability expectations increase, organizations are reexamining how their buildings perform, focusing on efficiency gains and implementing targeted energy efficiency services.

Instead of defaulting to simple equipment replacements or renewable installations, we focus first on how existing systems perform, emphasizing demand reduction strategies before considering additional renewable energy supply.

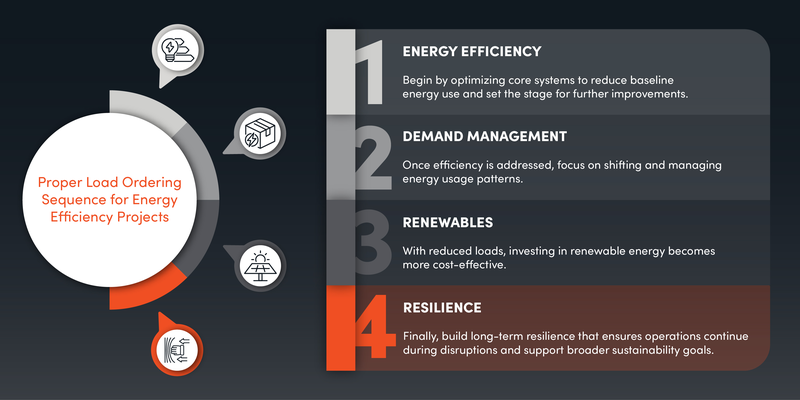

Proper load ordering sequence for energy efficiency projects

Reducing energy use starts with understanding where and how energy is consumed, and what drives that consumption. It is important to follow an energy and carbon reduction approach centered on proper load ordering sequence:

While some strategies can be implemented in parallel, taking a layered approach ensures systems work together, not against each other. This structure reduces capital costs, maximizes performance, and lays a smarter foundation for the future.

Case Study: Sutter Health Milles Peninsula Medical Center

At Mills Peninsula Medical Center, part of the Sutter Health Care system, we partnered to reduce energy intensity across a 600,000-square-foot hospital and medical office campus. Rather than beginning with expensive capital upgrades, we focused on optimizing existing systems, improving control sequences, and engaging the facility operations team in a culture of performance through training.

The 2 phases of retrofit work led to approximately a 33% total energy savings. The first phase focused on non-HCAI permit work such as control sequencing optimization. The second phase addressed lighting efficiency, power system monitoring, and correction of underlying boiler hydronic system and exhaust air flow control issues that had previously gone unnoticed. This work not only improved performance, but also vastly improved how the hospital functions and reduced facility maintenance costs.

Sustaining efficiency gains from energy improvement projects

Improving sustainability requires a thoughtful process, deep collaboration, and a commitment to ongoing optimization, not one-time fixes. Through measurement and verification (M&V), energy modeling, and use of EMCS real-time data, we can track performance and catch issues early. Fault detection and diagnostics (FDD) software, combined with ongoing support from an engineering team, quickly identifies operational issues and uncovers hidden inefficiencies. Meanwhile, training and process improvements enable facility staff to maintain those efficiency gains over time.

Energy Consulting Director

As Energy Consulting Director, Eric Nyenhuis is responsible for the technical development of energy projects, including coaching and leading project developers, energy engineers, and measurement and verification specialists. With more than 30 years of industry experience, he has a deep knowledge of building energy systems, energy master planning services, energy consulting, savings and financial analyses, retrofit scope of work development, and demand management and response.