Overview

Old Trapper has been producing beef jerky and other smoked meat snacks since 1969 at its campus in Forest Grove, Oregon.

Southland Industries has partnered with Old Trapper since 2015, delivering a range of new construction and renovation projects across its multi-building campus. These facilities serve a variety of functions, including offices, warehouses, food processing areas, cold storage, and more — each with its own technical and regulatory requirements.

Our Approach

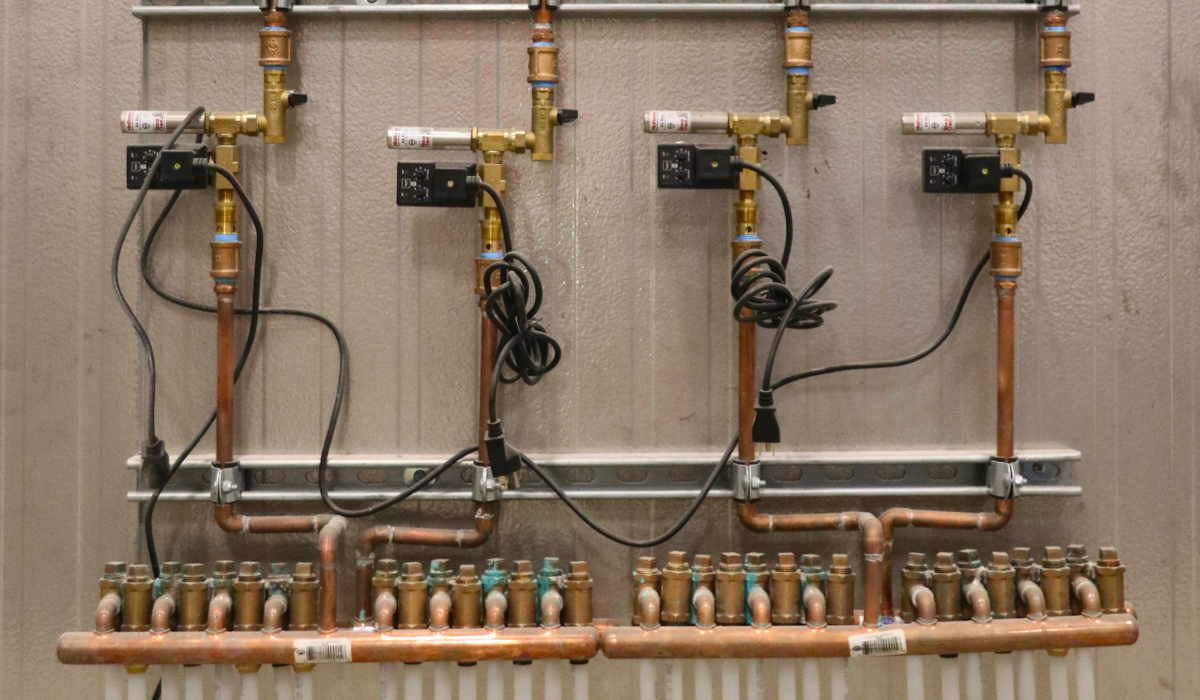

Most projects with Old Trapper have been design-build, with our teams providing full mechanical, plumbing, and controls scopes. Many of the buildings are multi-use spaces with specific material specifications based on U.S. Department of Agriculture (USDA) requirements, washdown protocols, and owner preferences.

Each project has required close coordination to connect utility systems to owner-furnished process equipment, like the level of planning needed for commercial kitchens. Notable projects delivered on the Forest Grove campus include:

- Phase II Factory Building F (2017)

- Wastewater Treatment building (2021)

- Warehouse Addition (2024)

- 4071 Smoke Oven Retrofit (2025)

During the Phase II Factory Building F project, we delivered the design-build mechanical and plumbing scopes for a major expansion. The work included a phased approach: phase one involved remodeling the existing facility, while phase two focused on constructing a new production facility and administrative offices.

The new facility was designed and built to meet updated USDA food safety standards. Nearly 100 percent of the production space is food grade. All structural, mechanical, and plumbing systems use stainless steel materials to support sanitary conditions.

Due to the tilt-up construction sequence, the slab was poured after the tilt walls were installed. All plumbing excavations occurred within the enclosed structure. As a result, the team relied heavily on detailed field coordination for the layout and installation of mechanical, electrical, and plumbing systems.

Completed in 2017, the advanced facility, one of the largest of its kind, enabled Old Trapper to significantly expand its production capacity in response to growing demand.

Result

Our longstanding partnership with Old Trapper has supported the company's growth and ability to meet rising demand. From expanding production capacity to improving facility performance and compliance, each project has helped strengthen operations across the Forest Grove campus.

Successful Partnerships

Owner: Old Trapper Smoked Products

General Contractor: Robert Evans Company

Architect: CIDA