Overview

Fort Riley is a premier training installation and the proud home of the 1st Infantry Division, the oldest continuously serving active-duty division in the U.S. Army. Spanning 150 square miles, the base supports extensive training operations and maintains combat-ready forces.

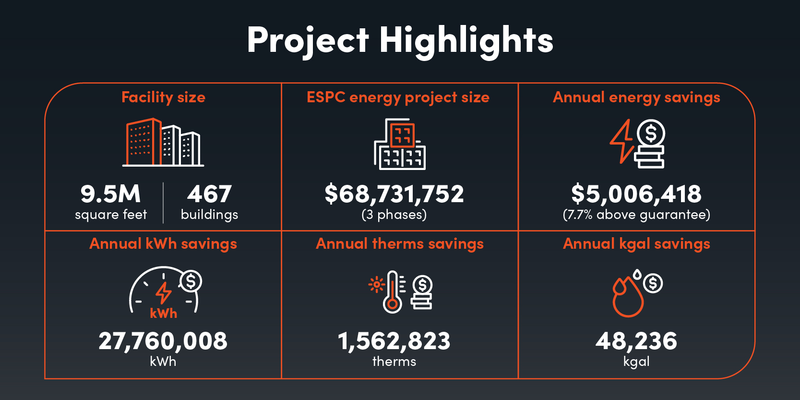

Southland executed a multi-phase Energy Savings Performance Contract (ESPC) that significantly reduced energy consumption, modernized aging infrastructure, and strengthened operational resilience at Fort Riley.

Our Approach

The project began with a comprehensive feasibility study that identified a wide range of energy conservation measures (ECMs) aligned with Fort Riley's objectives. Based on these findings, our team delivered in-house design, engineering, construction, commissioning, measurement and verification, and ongoing maintenance services.

Project ECMs included:

- HVAC Upgrades: Enhanced efficiency and performance of heating and cooling systems

- Infrared Heating: Installed energy-efficient heating solutions

- LED Lighting: Upgraded interior, exterior, street, and airfield lighting to LED

- Water Conservation: Implemented measures to reduce water usage

- Plumbing Improvements: Modernized fixtures and systems

- Recommissioning: Optimized existing systems for peak performance

- Building Automation: Integrated advanced building management systems

- Central Plant Upgrades: Expanded and modernized central utility plants

- Energy Management Control System: Deployed RMF-compliant systems for secure, efficient energy oversight

Result

All phases of the ESPC were executed on time, within budget, and without any lost-time accidents or disruptions to mission-critical operations. The project earned an "EXCEPTIONAL" CPARS rating across all categories: quality, schedule, management, and small business engagement.

Additionally, 60 percent of subcontracts were awarded to small businesses — 3 times the original 20 percent goal. These included Small Disadvantaged Businesses (SDB 8(a)), Women-Owned Small Businesses (WOSB), HUBZone Small Businesses, Veteran-Owned Small Businesses (VOSB), and Service-Disabled Veteran-Owned Small Businesses (SDVOSB). All awards were given to firms local to Fort Riley, reinforcing our commitment to supporting the regional economy.

Additional project results and benefits include:

- 24/7 operations and maintenance with a 2-hour response time for 2 central chilled water plants (1,500-ton and 1,100-ton capacity)

- First U.S. Army Corps ESPC IDIQ project to successfully integrate the Risk Management Framework (RMF), achieving system Authority to Operate (ATO)

"My working relationship with the Southland team was an outstanding experience. From the installation management team to the engineers and financial administrators to the CEO, all members were courteous, professional, and displayed enthusiasm for the project," said Joseph Rath, Project Manager USACE (HNC from PPQ, dated 7 August 2020).

Successful Partnerships

Owner: U.S. Army Corps of Engineers

General Contractor: Southland IndustriesAward-Winning Results

Fort Riley Awarded 2024 Federal Energy and Water Management Award

2022 Secretary of the Army Energy and Water Management Award | Energy Efficiency (ESPC)

2022 Federal Energy and Water Management Award | Project Award (ESPC)

2021 Secretary of the Army | Individual Exceptional Performance (Dan McCallister, ESPC COR)

2020 Secretary of the Army Energy and Water Management Award | Energy Efficiency (ESPC)

2019 Secretary of the Army Energy and Water Management Award | Energy & Water Resilience Program Effectiveness