What is a field printer?

A field printer is an automated layout tool that prints BIM plans directly onto a jobsite floor. It marks layout points for hangers and supports, floor openings, cores, and wall penetrations for mechanical, electrical, and plumbing subcontractors.

Utilizing technology like robots in construction can streamline our efficiency, maximize value, and improve team interaction on construction sites. Mike Vang, Superintendent, and Tanya Peddy, Virtual Field Technician Manager, share their insight about their experience utilizing these robots to efficiently lay out points onsite.

How field printers enhance construction layout

Automated point layout equipment works similarly to a Robotic Total Station, a traditional construction technology instrument commonly used to automate BIM layouts.

"It uses control points to set up its current location and then prints information relative to the setup. Attached to the robot is a prism which allows the laser tracker to lock onto its location. From there, the robot utilizes distances and angles to print the information relayed from the data collector onto the floor," said Tanya.

These robots are customizable — the field team can adjust font size, colors, and layout orientation. This feature empowers teams to print any BIM layout they design, specifically tailored to the task or project. The robot's rugged design, sensors, and long-lasting battery life ensure it can traverse hazardous jobsite conditions and avoid potential obstacles, allowing our teams to work efficiently and safely onsite.

Impact of robots in construction

Construction technology focuses on solving problems we know of — and those we are unaware of — on jobsites. There are numerous construction site impacts of layout robotics, including:

Efficiency

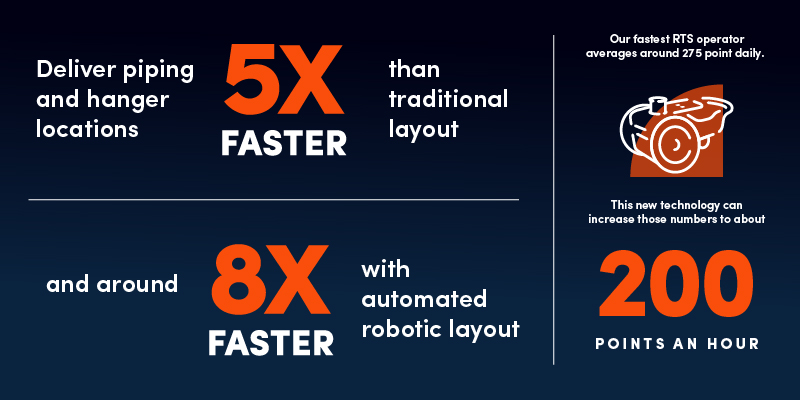

Field printers increase the number of points laid out in a certain period versus a traditional BIM layout approach, saving time during the construction layout process.

Safety

By eliminating the need for employees to bend down to mark BIM points, robots in construction enhance safety by reducing the risk of workplace injuries and improving ergonomics.

Tanya expressed, "With the ability to print the information on the ground, we keep our operators from bending down to mark each point, saving a significant amount of repetitive motion and reducing potential workplace injuries."

Quality

These field printers' precise layout, within one-eighth of an inch, impacts the quality of a contractor's construction layout and provides data collection and documentation.

"The robots give you real-time information on the number of point layouts per hour and document that data for historical use. It helps optimize costs by increasing productivity and efficiency," Mike said.

Innovation in construction layout

Leveraging the latest construction technology can improve collaboration and create true value for all members of the design, construction, and operations teams. The construction layout process has always been tedious, time-consuming, and error-prone. This process automation is just the beginning of improving efficiency.

"Robotics helps streamline data from BIM to the jobsite and provides progress updates of your employees' layouts. This technology helps streamline workflow and project outcomes," Mike said.

The field printers enable us to take a job that would traditionally take multiple people several days to complete into a one-person job completed in hours. With many construction companies facing challenges in recruiting for the skilled trades, robots in construction and similar applications can reduce strain on current employees, enhancing retention and employee sentiment.

"Construction is constantly advancing in new ways to be better, faster, and safer. The labor shortage is nothing new, but with help from these types of construction technology, we can make that gap a little bit smaller," Tanya said.

See a field printer in action here.

Senior Content Marketing Strategist

As Senior Content Marketing Strategist, Lindsay Janssen manages our content lifecycle. From ideation, creation, and editing through distribution, measurement, and maintenance, and creating a content strategy, she develops new and innovative ideas for our digital marketing channels.