The Challenge

On a hospital construction project, employees faced uncomfortable and unsanitary conditions with the typical jobsite toilet setups. Traditional portable restrooms were inadequate for a setting where sanitation and employee well-being were top priorities. To find a solution that improved hygiene, addressed logistical constraints of moving sanitation facilities across the jobsite, and keep costs manageable, a team member utilized his experience and innovative thinking.

Innovation through Experience – The 'Aha' Moment

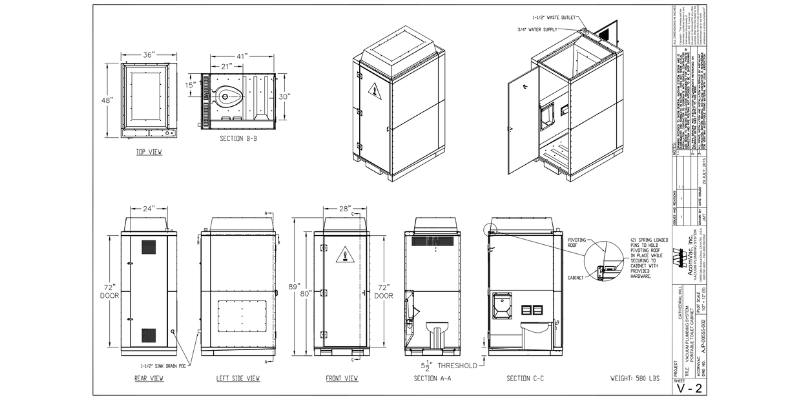

The breakthrough came from Matthew Davenport, a plumber and member of UA Local 38. Having firsthand knowledge of using jobsite toilets, Matt recognized their limitations. He envisioned a solution that prioritized hygiene, efficiency, and employee well-being: modular bathrooms. These compact, self-contained units provided privacy, cleanliness, and ease-of-use.

The collapsible design of the prefabricated restrooms allowed for easier transportation and efficient movement between floors, preventing contamination and spillage, solving a key logistical challenge.

The Bottom Line

The modular bathrooms not only solved pressing sanitation issues but also boosted employee morale by providing a more comfortable and hygienic environment. The design proved highly efficient for jobsite logistics and allowed for reuse across future projects, demonstrating the long-term value of the solution. By leveraging craft knowledge and user experience, the prefabricated restrooms drove meaningful change.

Senior Content Marketing Strategist

As Senior Content Marketing Strategist, Lindsay Janssen manages our content lifecycle. From ideation, creation, and editing through distribution, measurement, and maintenance, and creating a content strategy, she develops new and innovative ideas for our digital marketing channels.

Related Reading