What is decarbonization?

Decarbonization is an approach to design, construction, and facilities operation that is focused on reducing carbon emissions. Whereas prior energy efficiency efforts have aimed to reduce overall energy (BTU) consumption or a facility's utility cost, decarbonization specifically aims at eliminating carbon emissions. Sustainability goals align with this approach by reducing the environmental impact of facilities.

Carbon emissions are divided into three categories:

Scope 1 Emissions are directly related to the facility. For a typical building, the majority of Scope 1 Emissions result from onsite combustion of natural gas for heating and domestic water heating.

Scope 2 Emissions are created at the source of the utilities that serve the facility. For a typical building, the majority of Scope 2 Emissions result from production of electricity at a power plant that was then transmitted to and consumed at the facility.

Scope 3 Emissions are the result of activities of the users of the facility. The majority of Scope 3 Emissions are from transportation, including commuting and air travel of facility users in pursuit of their work.

Executive Order 14057, as signed by President Biden in December 2021, sets decarbonization requirements for federal facilities as a strategy to lead by example on the mission to reduce overall U.S. carbon emissions. The order includes specific goals, such as a "65 percent reduction in Scope 1 and Scope 2 Emissions by 2030" and requires agencies to prepare plans and report progress annually towards these achievements. These efforts emphasize sustainability practices across federal facilities.

While municipalities, colleges, universities, school districts, and private firms are not covered by the executive order, many of these entities have similar decarbonization goals or initiatives in pursuit of environmental stewardship, improved air quality, and increased enrollment and revenue. Sustainability programs in these sectors are also essential for reducing their carbon footprint and driving environmental responsibility.

Decarbonization also goes hand-in-hand with tackling the financial constraints and deferred maintenance backlogs that many public entities face, including replacing old equipment with new more efficient equipment and implementing more reliable and resilient systems.

Guidelines for effective decarbonization programs

In addition to providing guidelines for effective decarbonization programs, a case study of how the City of Chico, located in Northern California, is provided below. This case study exemplifies how the City implemented their decarbonization program through an achievable and phased approach.

Guideline 1

Whether your entity is federal, public, or private, the first step in implementing a decarbonization program is to define the goals and stakeholders who will benefit from the project and identify constraints that may limit work.

The City of Chico’s goals for their energy efficiency and decarbonization program with Pacific Gas & Electric (PG&E) and Southland Industries were:

Replace old natural gas HVAC equipment with new more reliable and efficient heat pumps to reduce maintenance, improve occupant comfort.

Reduce energy costs for the wastewater treatment facility.

Make progress towards the City’s net zero energy goals with energy reductions and electrification in advance of added renewable electricity generation.

Guideline 2

Once the goals, stakeholders, and constraints are defined, project leadership should work together to identify a project development and implementation plan that maximizes achievements of the goals and benefits to the stakeholders while remaining within the identified constraints.

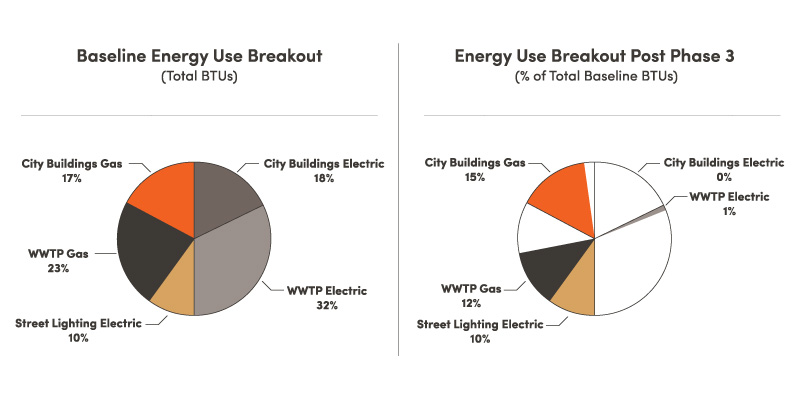

PG&E and Southland worked closely with the City to identify specific projects that met the stated goals with input from the stakeholders. The selected Energy Conservation Measures (ECMs) included:

Replacement of HVAC equipment and HVAC controls systems throughout the City’s buildings with new high efficiency equipment and new controls systems.

Right-sized replacement of aeration blowers and upgraded aeration distribution to achieve more efficient treatment with reduced electrical consumption at the wastewater treatment plant (WWTP).

Replacement of the maintenance and energy intensive sludge heaters with a new cogeneration system and high efficiency natural gas backup boilers at the WWTP.

Replacement of an old and underperforming PV system at the WWTP with a new larger system.

Installation of new PV systems at multiple facilities to offset nearly all facility electrical consumption.

Installation of a cogeneration system at the WWTP to create electricity and heating hot water from biogas that was currently being flared.

Guideline 3

Once the desired project scope is defined with support from the stakeholders, acknowledging the financial constraints is critical in the development of your project. Ignoring this step risks the development of a decarbonization masterplan with no real financial path for implementation — a fate many entities are currently facing.

In order to satisfy the City of Chico's desire to see a demonstrated return on investment for the project prior to making a large financial commitment, the project was split into three phases for financing and implementation.

The simpler and more modest HVAC and WWTP equipment replacement was selected for phase one, with the larger investment in renewable energy reserved for phase two. Finally, the more complex cogeneration system was saved for phase three when the City was fully confident in the results of the first two phases.

Similarly for project financing, the City used PG&Es on-bill financing program for phase one before funding phases two and three directly from the City budget. This phased approach of proving the results of each project before investing in the next gained the support and confidence of the stakeholders who championed each subsequent phase through City Council votes and budget allocations as required for funding and implementation.

After initial project development and approval and funding has been achieved, the project moves to the implementation phase. While quality control/assurance is an important part of any design and construction project, it is even more critical for decarbonization work where the success of the project is not just the installation of the equipment or systems, but the actual performance of the system.

Care must be taken to ensure that equipment specifically selected for decarbonization, such as high efficiency or electrified HVAC systems, are not replaced for lower cost systems during value engineering reviews that may achieve deferred maintenance goals, but not decarbonization results. Similarly, equipment commissioning must happen concurrently with training and education for stakeholders and affected end-users to provide understanding of why new equipment may operate differently or provide different conditions. This includes education on how to adjust use or maintenance of new systems to ensure decarbonization benefits persist over the long term.

For the City of Chico, the facilities department was instrumental in the success of the project and took an active approach to participation in the equipment commissioning process, learning how to correctly operate, monitor, and track the new systems and educate the end-users on how the changed system types may affect their daily work or perceived comfort. For example, this meant working with end-users to help them understand that the electrified heating equipment may take longer to heat up offices during cold mornings, but they ultimately provide more consistent temperatures while reducing emissions and costs for the City. This insight helped stakeholders accept and adjust to the new equipment.

By defining goals and stakeholders, developing a decarbonization plan, and acknowledging financial constraints, public entities can work toward successfully implementing a decarbonization program to successfully reach energy and sustainability goals.

Business Acquisition Manager

As Business Acquisition Manager, Jeff Schaller focuses on developing campus energy upgrade projects through energy savings performance contracts, public-private partnerships (P3), and alternative procurement methods. As a licensed mechanical engineer with over 18 years of experience, he has led the development and execution of numerous successful energy projects for municipal, state, and federal government buildings, correctional facilities, universities, and public schools across the United States.