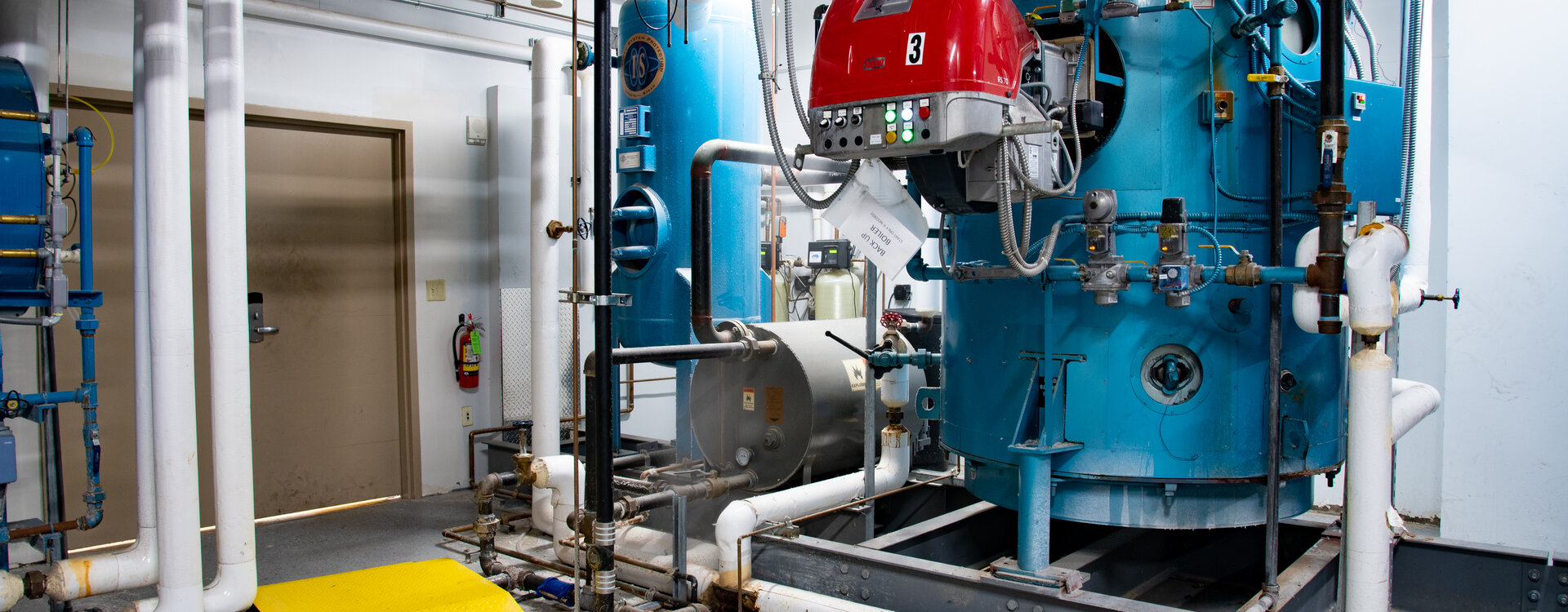

For over 100 years, steam systems have been used to provide hot water, building heat, sterilization, humidification, etc. for various facilities. Over the last 10 years, we have started to see a trend that moves away from proven steam systems towards more hot water boilers for certain customers and industries.

Evaluating the increasing trend of choosing hot water boilers

In the old days, steam was heavily used by the U.S. Navy, so it was easy to find a steam maintenance technician that had served in the Navy to properly maintain and service a steam system. As the U.S. Navy has moved away from steam and without proper steam system maintenance being taught in many technical schools, the number of properly trained maintenance personnel has decreased. In addition to these recent trends and with many states required to have a boiler operator on staff 24/7, it can be easier to maintain a hot water system than a steam system.

With the need to be more sustainable and reduce greenhouse gas emissions, a condensing hot water boiler can be more efficient at the point of generation (90 percent or more depending on return water temperature) versus a steam boiler (82 percent before adding energy efficient options — economizers, blowdown heat recovery, etc.). Due to lower pressures and less energy per pound, a hot water system is also usually perceived as a safer system than steam.

However, there are drawbacks to consider when using hot water boilers. Hot water boilers are limited in size and turndown, so more boilers and more floor space are required as opposed to steam boilers. The life of a condensing boiler is based on continuous maintenance and cleaning of the condensing side. Most hot water boilers only have a 7–15-year life span (depending on make and model) and are not repairable, but a steam boiler can last for more than 30 years. Finally due to the lower energy per pound in hot water systems, larger pumps and hot water piping are required — versus a similar steam to water heat exchanger system.

To reap the increased efficiency benefits of condensing hot water boilers, the return water temperature needs to be as low as possible, which may not occur either due to oversizing of equipment or incorrect control sequences. Water treatment is also key and must be maintained properly to ensure the life of a hot water condensing boiler.

Examining why and how steam systems are still used

Although there is an increasing trend of installing hot water boilers, steam is still used in many industries for a variety of reasons. Steam can provide larger amounts of heat energy quickly without using pumps to distribute it at higher temperatures than hot water systems, steam is sterile, and steam can be used to easily control humidity in an area. Steam is also still the most efficient heat transfer media.

For specific customers and industries, steam systems can still be the best option:

- Any facility that already has a steam system, including healthcare, hospitality, manufacturing, university, etc.

- Central Utility Districts that provide steam and other utilities to customers, including large universities and healthcare campuses with multiple energy plants providing utilities to each building

- Food and beverage customers

- Refineries and chemical plants

- Pharmaceutical facilities

- Semiconductor manufacturing

Taking a hybrid approach with steam systems and hot water boilers

For new healthcare facilities, sometimes a hybrid approach is implemented. Heating and/or domestic hot water can be provided by condensing hot water boilers. Humidification is provided with electric-generated humidifiers, and steam for biomed sterilizers and washers is provided either individually by the manufacturer or with a smaller clean steam generator. Depending on the size of the generators, these could be electric. In the facility, if a laundry is installed, a small steam system is required.

With these different types of equipment, additional maintenance knowledge may be needed. Often, instead of multiple different systems, it would be easier for facilities to have just one single steam system to handle all the different processes and facility requirements.

Examining emerging boiler trends

Looking back on traditional approaches and examining the recent trends of the past 10 years, what does the future hold? Within the industry, there are discussions of using heat pumps to provide hot water and maybe low-pressure steam, but currently these processes are more expensive than standard steam and hot water boiler systems.

An alternate perspective on the trend towards condensing hot water boilers is for teams to increase their steam system expertise, leading this niche market and expanding offerings to current and new customers.

This article is part of a boiler blog series. Click here to read part one.

Steam Applications Specialist

As Steam Applications Specialist, Robert Crone is an in-house resource to assist with all steam and condensate projects. His workload is multi-faceted as he assists with the proper design, estimating, training, installation, and commissioning of steam and condensate systems. In addition, he works with our business development and service account managers to partner with our customers when upgrading their steam systems.